Organic food producer

This customer currently burns diesel to generate steam at 170 °C to operate its production lines for producing organic baby food. With this heat solution we will support our customer in it’s objective to reduce carbon emission and become less reliant on fluctuating fossil fuel prices.

Project overview

Suncom delivers a heat solution enabling the customer to reduce it’s fossil fuel usage. The heat solution consist of the SunFleet H300 series with 40 SunArcs a SunTES H300 and an advanced sun-tracking system. The overall system is projected to generate approximately 400,000 kWh thermal annually. The project has also been granted the RVO DHI-subsidy.

Agricultural customer

Previously, this customer’s operations relied on a pellet boiler to heat water up to 80 °C. This project has supported the customer’s objective towards a more sustainable operation while reducing energy costs.

Project overview

Suncom provides a comprehensive turnkey solution tailored for this customer. This solution has the capability to completely replace the customer’s current heating method (a pellet boiler) with our advanced solution. The integrated system comprises 50 SunArcs, a SunTES 100 (our Thermal Energy Storage), a heat pump, and an advanced sun-tracking system. The overall system is projected to generate approximately 460,000 kWh thermal annually.

- 50 SunArcs

- Insulated buffer tank

- Heat pump

- Advanced sun-tracking system

The project is structured into three distinct phases: engineering, supply and installation, and commissioning. Our target is to achieve full operational status by the conclusion of 2023, thereby facilitating the customers transition towards complete sustainability.

This project has also been granted the Hernieuwbare Energie Subsidie (HER+), a subsidy program specific to the Netherlands, further underscoring our commitment to sustainable solutions.

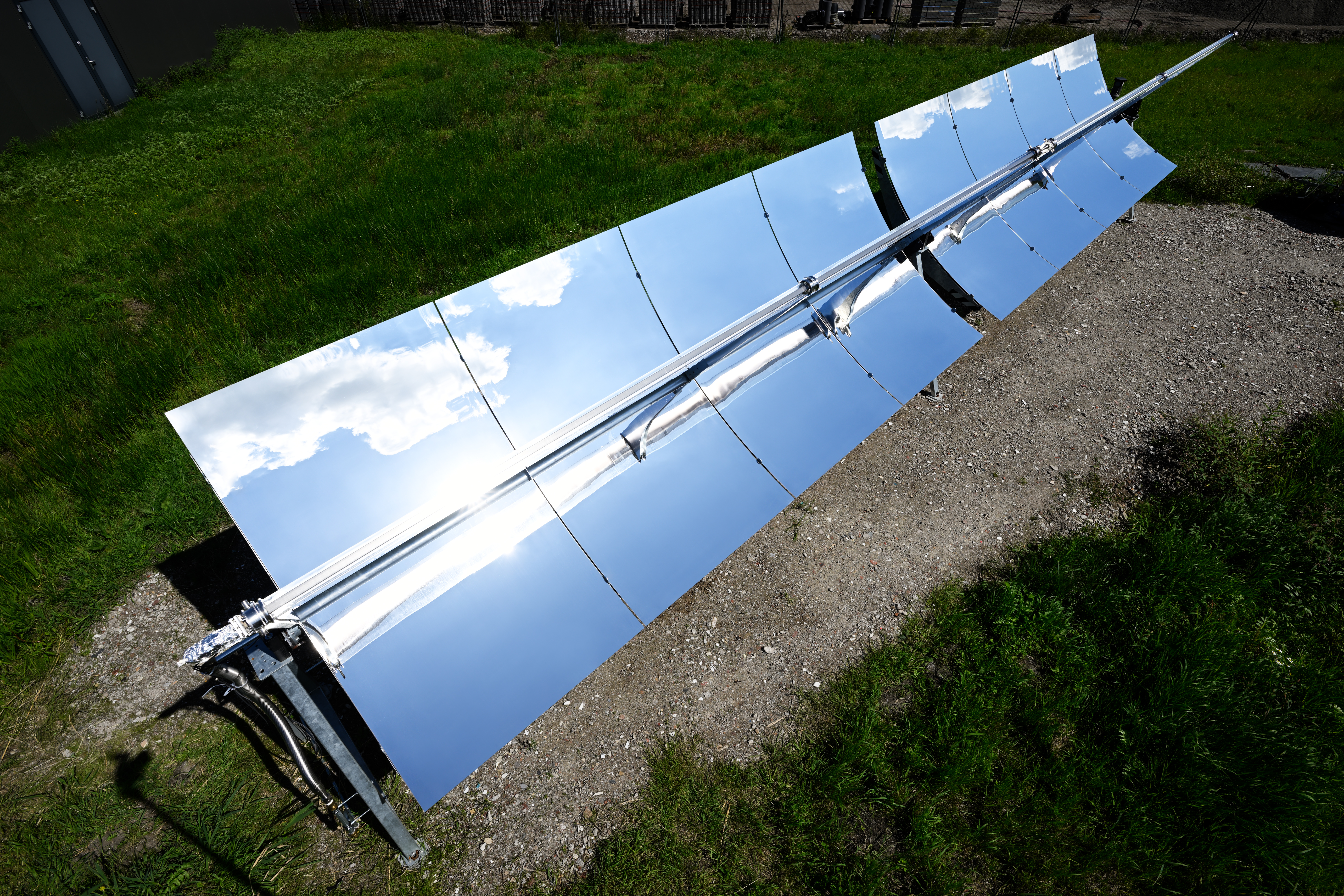

Houten facility

In early 2023, we successfully engineered, constructed, and tested a pre-production setup at our Houten facility.

Project overview

This system comprises:

- 2 SunArcs

- A SunTES 100 Thermal Energy Storage

- Our advanced sun-tracking system

It efficiently heats water to temperatures of up to 100 °C, storing the heat for multiple days.

The pre-production setup demonstrates an impressive output, reaching up to 17 kW peak power with 24 m2 of mirror surface and converting an impressive 71% of sunlight into heat.

Most importantly, this successful pre-production setup signals our readiness for mass production.